Can laser cut deburring process metal

Yes, laser cutting can deburr metal. Lasers can create a very precise and smooth cut on metal surfaces, which can eliminate the need for traditional deburring methods. This process can be used on a variety of metals, including aluminum, stainless steel, and carbon steel.

Laser cutting is a technology that has been around for decades, but it’s only in recent years that it’s become widely used in the manufacturing industry. Laser cutting is a process of using a laser to cut through material. The laser beam is generated by a high-powered laser source and is directed at the material to be cut. The material is then melted, burned, or vaporized by the laser beam, leaving a clean edge.

Laser cutting is often used to cut metals, but it can also be used to cut other materials, such as wood, plastics, and glass. Laser cutting has many advantages over other methods of cutting, such as waterjet cutting or plasma cutting. It’s more precise, can be done faster, and doesn’t require any special tools or training.

Common problems and solutions of laser cut deburring

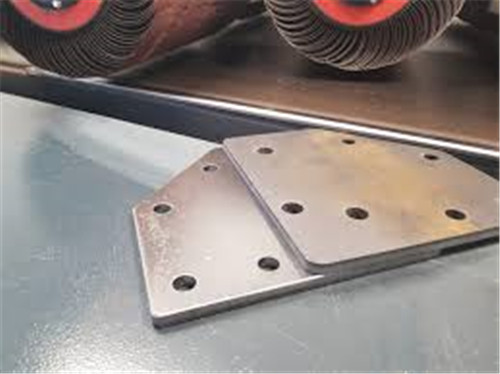

Laser cut deburring is a process that can be used to remove burrs from metal parts. Burrs are sharp edges that can be left behind after the laser cutting process. These sharp edges can cause injuries and can also damage the parts that they are attached to.

There are several common problems that can occur during laser cut deburring. These problems include:

- Parts sticking together: This problem can occur when the laser cuts through multiple layers of metal at once. When this happens, the parts can become stuck together.

- Parts not being cut cleanly: This problem can occur if the laser is not calibrated correctly. If the laser is not calibrated correctly, it will not cut through the metal cleanly and will leave behind jagged edges.

- Parts warping: This problem can occur if the metal is not heated evenly during the laser cutting process. If the metal is not heated evenly, it can warp and become misshapen.