|

Types of Edge Banding Corner Rounding Machines |

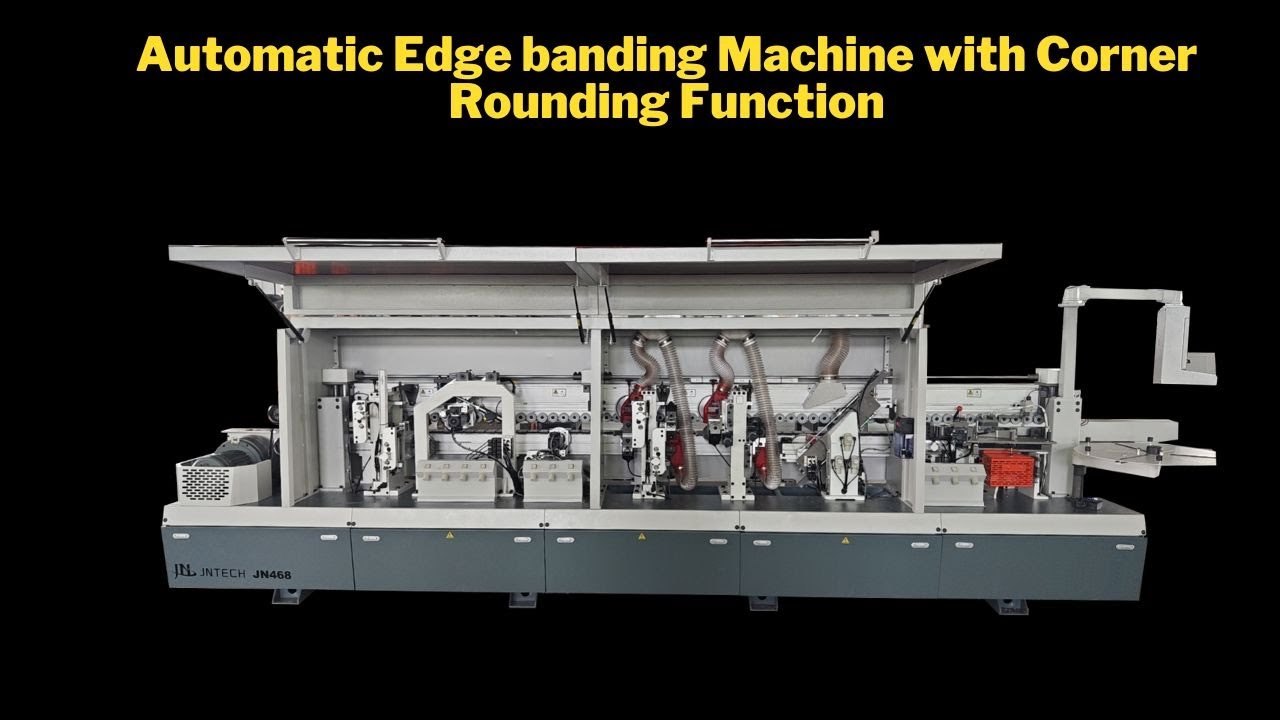

When it comes to edge banding and finishing, having the right tools and equipment is crucial. One essential machine to consider is the edge banding corner rounding machine. This versatile piece of equipment plays a vital role in achieving a professional and polished finish for your woodworking projects. But with so many options available in the market, how do you choose the right one?

Edge banding corner rounding machines are specifically designed to trim and round the corners of edge banded panels. These machines ensure that your edges are smooth, free of any roughness, and seamlessly blend in with the rest of the material. This attention to detail enhances the overall quality of your finished product and gives it a professional look.

1. Machine Capability: Consider the size and thickness of the materials you typically work with. Ensure that the machine you choose can handle the dimensions and thicknesses you require.

2. Corner Rounding Options: Different machines offer various corner rounding options. Some machines can round only one corner at a time, while others can round multiple corners simultaneously. Determine which option aligns with your specific needs.

3. Efficiency and Speed: Look for a machine that offers efficient and fast corner rounding capabilities. Pay attention to the machine's specifications and performance to determine if it can meet your production demands.

4. Durability and Quality: Invest in a machine that is built to last. Look for robust construction, quality components, and positive customer reviews to ensure the machine's durability and reliability.

5. Additional Features: Some machines offer additional features such as dust extraction systems, automatic feeders, and adjustable settings. Consider these features based on your preferences and the specific requirements of your woodworking projects.

By considering these factors and doing thorough research, you can choose the right edge banding corner rounding machine that meets your needs and helps you achieve exceptional results in your woodworking projects. Remember to compare different brands, read reviews, and seek recommendations from other professionals in the woodworking industry.

Are you in search of the perfect edge banding corner rounding machine but feeling uncertain about which one suits your needs best? Let us be your guide, offering a detailed exploration of the various options, empowering you to make an informed choice.

Mechanical edge banding corner rounding machines reign supreme among woodworking professionals. These electric-powered workhorses guarantee meticulous and efficient edge rounding. Equipped with automated motorized feed systems, they seamlessly guide your workpieces, ensuring unwavering precision. The versatility of mechanical machines means they can handle a range of edge thicknesses and materials with ease.

For hobbyists and small-scale woodworking operations, manual edge banding corner rounding machines offer an economical alternative. While they require manual operation, the results they yield are nothing short of impressive when handled correctly. Compact and portable, these machines provide convenience without compromising quality, making them ideal for those working in limited spaces.

Selecting the right edge banding corner rounding machine hinges on several considerations: the volume of work, desired precision, and budget constraints. Compatibility with your edge banding materials is paramount, as different machines may have specific requirements or limitations. Whether you opt for the mechanical marvel or the manual champ, investing in a top-tier machine will elevate your woodworking projects, enhancing efficiency and delivering professional results. Take the time to explore and compare various models, delve into customer reviews, and don't hesitate to seek expert advice to ensure you choose the perfect machine tailored to your specific needs.

Make your woodworking dreams a reality with a meticulously selected edge banding corner rounding machine.

When it comes to choosing the right edge banding corner rounding machine, there are several key features to consider that can make a significant difference in the efficiency and quality of your work. Here are the top features to look for:

Efficiency: One of the most important factors to consider is the machine's capacity and speed. This refers to how many edges it can handle at once and how quickly it can complete the task. Look for a machine that can handle the volume of work you expect, and choose a speed that aligns with your production needs.

Adjustability: Consider whether the machine allows for easy adjustments in terms of pressure, feed rate, and temperature control. This will give you the flexibility to work with a wide range of materials and achieve the desired edge quality.

Versatility: If you frequently work with edges that require corner rounding, it is essential to choose a machine that can perform this task effectively. Look for features like adjustable rounding radius and the ability to handle various thicknesses of materials.

Precision: The accuracy of the roundover profile is crucial for achieving a professional finish. Look for a machine with precision engineering and features that ensure consistent and precise corner rounding.

Advanced technology: Some edge banding corner rounding machines come with advanced technology features like digital controls and automatic adjustment systems. These can greatly enhance the ease of use and accuracy of the machine, saving you time and effort in setup and operation.

In conclusion, when choosing an edge banding corner rounding machine, consider factors such as machine capacity and speed, corner rounding capabilities, and advanced technology features. By selecting a machine that meets your specific needs and requirements, you can improve the efficiency and quality of your edge banding process.

Using an edge banding corner rounding machine requires careful attention and adherence to specific guidelines. Here are some tips to help you achieve optimal results:

1.Read the instructions: Before operating the machine, it is crucial to thoroughly read and understand the manufacturer's instructions. Familiarize yourself with the machine's controls, safety features, and recommended operating procedures.

2.Choose the right settings: Adjust the machine settings according to the thickness and type of the edge banding material you are using. Follow the manufacturer's recommendations for speed, temperature, and pressure settings to ensure a clean and precise result.

3.Feed the material correctly: Properly align the edge banding material with the machine's feed system. Make sure the material is straight and evenly positioned to prevent uneven cutting, chipping, or damage to both the banding material and the machine itself.

4.Ensure proper ventilation: Some edge banding materials can emit fumes during the heating process. To maintain a safe working environment, ensure proper ventilation in your workspace. Use a fume extraction system or work in a well-ventilated area.

To keep your edge banding corner rounding machine in optimal condition, regular maintenance and cleaning are essential. Here are some tips to help you maintain your machine:

1.Clean the machine after each use: Remove any leftover adhesive, dust, or debris from the machine's components, including the glue pot, pressure rollers, cutter heads, and feed system. Use a soft brush or compressed air to ensure thorough cleaning.

2.Inspect and replace worn-out parts: Regularly inspect the cutter heads, pressure rollers, and any other crucial parts for signs of wear and tear. Replace any worn-out or damaged parts to ensure consistent performance and prevent potential issues.

3.Apply lubrication: Lubricate the moving parts of the machine regularly to reduce friction and promote smooth operation. Use lubricants recommended by the manufacturer to prevent damage to the machine.

4.Schedule professional servicing: Engage a professional technician to perform regular servicing and maintenance checks on your edge banding corner rounding machine. This will help identify any potential issues and ensure that your machine operates at its best.

By following these usage and maintenance tips, you can prolong the lifespan of your edge banding corner rounding machine and achieve consistent, high-quality results in your woodworking projects.

Before embarking on the journey of choosing an edge banding corner rounding machine, it is important to determine your budget. This will help you narrow down your options and make a more informed decision. Consider how much you are willing to invest in this piece of equipment based on your business needs and financial capabilities. It's important to strike a balance between quality and affordability.

Several factors can influence the price range of edge banding corner rounding machines. Understanding these factors will help you make a more informed decision and prevent any surprises down the line.

1.Machine features and capabilities: The more advanced and sophisticated the features of the machine, the higher the price. Consider the specific features that are important for your business and be prepared to invest accordingly.

2.Brand reputation: Established and reputable brands often come with a higher price tag due to their reputation for quality and reliability. While it may be tempting to opt for a cheaper unknown brand, it's important to consider the long-term performance and support offered by reputable brands.

3.Size and capacity: Larger machines with higher production capacities tend to be more expensive. Evaluate the size and capacity requirements of your business to ensure you choose a machine that meets your needs without overpaying for unnecessary features.

4.Technical support and warranty: Consider the level of technical support and warranty offered by the manufacturer. While these may not directly impact the upfront cost, they can influence the overall value and peace of mind you get from your investment.

5.Market demand and competition: The market demand and competition within the industry can also affect the price range of edge banding corner rounding machines. Research the market to get an idea of the average price range and make sure you are getting fair pricing.

By considering your budget and the various factors that affect the price range of edge banding corner rounding machines, you can make a more informed decision and choose the right machine that meets your needs and aligns with your financial capabilities.

When it comes to choosing the right edge banding corner rounding machine, there are several factors to consider. Here are some important considerations to help you make an informed decision:

1.Machine Size and Capacity: Determine the size and capacity of the machine based on your specific needs. Consider the size of the materials you will be working with and ensure that the machine can handle them efficiently.

2.Quality and Durability: Look for a machine that is built to last and made from high-quality materials. A durable machine will ensure that it can withstand the rigors of daily use and provide reliable performance.

3.Ease of Use: Consider the user-friendliness of the machine. Look for features such as a clear user interface, intuitive controls, and easy adjustment mechanisms. A machine that is easy to operate will save you time and effort.

4.Versatility: Evaluate the machine's capabilities and determine if it can handle a variety of edge banding and corner rounding tasks. Look for features such as adjustable speed, different cutting profiles, and the ability to work with different types of materials.

It's important to consider your specific needs, budget, and the features that are most important to you when comparing different models. Keep in mind that higher-priced machines often come with additional features and capabilities, but it's not always necessary to invest in the most expensive option if it doesn't align with your needs.

In conclusion, choosing the right edge banding and corner rounding machine requires careful consideration of factors such as size, quality, ease of use, and versatility. By evaluating these factors and comparing different models, you can make an informed decision that will meet your specific requirements and help you achieve professional results in your woodworking projects.

In conclusion, choosing the right edge banding corner rounding machine is a crucial decision for anyone in the woodworking industry. By considering factors such as machine type, features, budget, and reputation, you can make an informed decision that will improve productivity and quality in your woodworking projects. With the right machine, you can achieve professional-looking finishes and save valuable time and effort.

Throughout this comprehensive guide, we have covered the essential factors to consider when choosing an edge banding corner rounding machine:

1.Determine your specific needs: Consider the types of materials you will be working with, the size of your projects, and the complexity of the edges you need to round.

2.Choose the right machine type: There are different types of edge banding corner rounding machines available, such as manual, semi-automatic, and automatic machines. Select the one that aligns with your production requirements and skill level.

3.Consider the features: Look for features like adjustable speed, easy-to-use controls, quick changeover, and compatibility with various edge banding materials.

4.Set a budget: Determine your budget and find a machine that offers the best value for your investment. Consider the long-term benefits and return on investment.

5.Research reputable brands: It's important to choose a machine from a reliable and established manufacturer known for producing high-quality equipment and excellent customer support.

When making your final decision, prioritize a machine that meets your specific requirements in terms of machine type, features, budget, and brand reputation. Consider reaching out to industry experts or seeking recommendations from other woodworking professionals to get insights and opinions.

Remember, investing in the right edge banding corner rounding machine is an investment in the success and efficiency of your woodworking projects. By choosing wisely, you can enhance the quality of your work and streamline your production process. So take the time to research, compare, and evaluate your options to find the perfect machine that will meet your needs and deliver exceptional results.

Related news

CONTACT US

Address

53 Peng'an Road, Pingyao Town,

Hangzhou, China

kenny.gong@vip.163.com

17767176257@163.com

Phone

Phone:+86 17767171031

+86 13968085257

Fax:0571-88524367

JONSEN SANDER is one of the leading Sheet Metal Deburring Machines, Grinding Machine, Wide Belt Grinding Machine, Edge Rounding Machines Manufacturers, Factory and Suppliers, Our product quality has passed international certification, and the price is affordable, welcome to call and order our products wholesale.

Copyright: Hangzhou Xiangsheng Abrasive Machine Manufacturing Co., Ltd. Support By Hangzhou Great Master