|

Benefits of Deburring Machines Types of Sheet Metal Deburring |

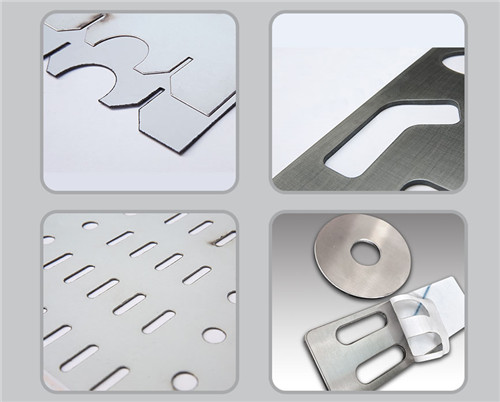

Precision in sheet metal fabrication is crucial across various industries, including automotive, aerospace, and construction. The quality and accuracy of fabricated metal parts significantly affect the performance, durability, and efficiency of the final product. Achieving precise dimensions, angles, and tolerances is essential to ensure proper fit, functionality, and compatibility with other components, ultimately optimizing the product's performance.

Deburring machines play a critical role in enhancing precision during the sheet metal fabrication process. These machines are specifically designed to remove burrs or sharp edges from metal parts, improving the overall finish and accuracy of the fabricated components.

Deburring machines utilize various methods such as abrasive belts, brushes, or vibratory tumbling to eliminate burrs and smooth the edges of metal parts. They are equipped with precise controls and adjustments that allow for accurate and consistent deburring. These machines can handle a wide range of metal materials and complex shapes, ensuring uniform deburring and adherence to required specifications.

Deburring machines operate by using abrasive belts, brushes, or vibratory tumbling to remove burrs and smooth the edges of metal parts. The machines are designed with precision controls and adjustments that enable precise and consistent deburring. Regardless of the material or shape of the metal parts, these machines can ensure uniform deburring and meet the required specifications.

Deburring machines also contribute to the longevity and durability of fabricated parts. By removing sharp edges and burrs, these machines eliminate potential stress concentration points that can lead to premature failures or reduced performance. This enhances the overall quality and reliability of the final product.

Moreover, deburring machines improve the efficiency and productivity of the sheet metal fabrication process. By automating the deburring process, they eliminate the need for manual labor, reducing the time and effort required. This allows manufacturers to increase their production capacity and meet tight deadlines effectively.

Overall, precision is crucial in sheet metal fabrication across various industries. Deburring machines play an essential role in achieving this precision by removing burrs and enhancing the finish of fabricated parts. By investing in deburring machines, manufacturers can ensure high quality, functional, and long-lasting products, gaining a competitive edge in the market.

Deburring machines have become an integral part of the sheet metal fabrication process by enhancing safety and improving aesthetics. With their ability to remove burrs and sharp edges from metal parts, these machines eliminate potential safety hazards and reduce the risk of injuries for workers involved in handling the fabricated components. Additionally, the deburring process enhances the overall appearance of the metal parts, giving them a smooth and polished finish that significantly enhances their aesthetic appeal.

The use of deburring machines has a significant impact on the functionality and performance of sheet metal components. By effectively smoothing out rough edges and removing burrs, these machines ensure that the parts fit accurately and function at their optimum level. The elimination of burrs also reduces friction and wear between components, increasing their lifespan and enhancing their overall performance and reliability.

• Accuracy and consistency: Deburring machines are equipped with precise controls and adjustments, allowing for accurate and consistent deburring of metal parts. This ensures that the dimensions, angles, and tolerances of the fabricated components meet the required specifications.

• Longevity and durability: Deburring machines contribute to the longevity and durability of the fabricated parts by eliminating potential stress concentration points that can lead to premature failures or reduced performance.

• Efficiency and productivity: By automating the deburring process, these machines reduce the need for manual labor, resulting in increased efficiency and productivity. Manufacturers can meet tight deadlines effectively and increase their production capacity.

| Specification | Description |

| Power | Deburring machines come in various power options to cater to different workloads and types of materials. |

| Deburring method | There are different deburring methods available, such as mechanical, thermal, or chemical, depending on the specific needs of the application. |

| Speed and feed controls | Different machines offer variable speed and feed controls, allowing for precise adjustments based on the material being deburred. |

| Size and capacity | Deburring machines come in various sizes and capacities to accommodate different workpieces and production requirements. |

Deburring machines have become indispensable in achieving precision in sheet metal fabrication. They improve safety, enhance aesthetics, and ensure the functionality and performance of fabricated components. By carefully considering the important features and specifications of deburring machines, manufacturers can select the most suitable option for their specific needs and produce high-quality products that meet industry standards.

Manual deburring techniques involve using hand tools to remove burrs and sharp edges from sheet metal components. This method requires skilled operators who can manually smooth out rough edges and eliminate burrs. Some common manual deburring tools include files, abrasive pads, and hand scrapers. While manual deburring can be effective for smaller projects or intricate parts, it tends to be time-consuming and labor-intensive. It also carries a higher risk of human error, as the consistency and accuracy of the deburring process depend on the operator's skills.

Automated deburring methods utilize specialized machinery to remove burrs and sharp edges from sheet metal components. These machines offer several advantages over manual deburring, including increased efficiency, precision, and consistency. Automated deburring machines can handle larger workloads and significantly reduce labor costs by streamlining the deburring process. They use various techniques such as mechanical, thermal, or chemical methods to achieve efficient deburring. The choice of deburring method depends on the specific requirements of the application.

Automated deburring machines are typically equipped with advanced controls, allowing for precise adjustments to dimensions, angles, and tolerances. This ensures that the fabricated components meet the required specifications consistently. The use of automated deburring machines also enhances safety by reducing the risk of injuries associated with manual deburring. These machines provide a safer working environment for operators by eliminating direct contact with sharp edges and reducing operator fatigue.

In conclusion, sheet metal deburring can be done manually or using automated machines. While manual deburring requires skilled operators and is time-consuming, automated deburring offers increased efficiency, precision, and consistency. The choice between manual and automated deburring depends on the project size, complexity, and specific requirements. Implementing the appropriate deburring method is crucial to achieve high-quality sheet metal components that meet the required standards.

Deburring machines play a crucial role in streamlining the sheet metal fabrication process, leading to increased efficiency and time savings. These automated machines are designed to remove burrs and sharp edges from sheet metal components, eliminating the need for manual labor and reducing the overall production time.

One of the main advantages of using deburring machines is their ability to handle larger workloads. These machines can process a significant number of sheet metal components in a shorter amount of time, resulting in increased productivity. By automating the deburring process, manufacturers can achieve faster turnaround times and meet tight project deadlines.

Deburring machines also offer higher precision and consistency compared to manual deburring techniques. These machines are equipped with advanced controls that allow for precise adjustments to dimensions, angles, and tolerances. This ensures that the fabricated components meet the required specifications consistently, reducing the need for rework and ensuring high-quality end products.

Several industries have witnessed the benefits of using deburring machines in terms of increased efficiency and time savings. For example, in the automotive industry, deburring machines have enabled manufacturers to produce precision components with reduced lead times. These machines have also contributed to improved product quality and reduced production costs.

In the aerospace industry, deburring machines have played a crucial role in achieving faster production rates and maintaining stringent quality standards. The use of automated deburring machines has significantly reduced the time required to complete complex assembly projects, ensuring on-time delivery of aircraft components.

Similarly, in the electronics industry, deburring machines have helped manufacturers meet the high-demand requirements for precision components. These machines have enabled faster production cycles, ensuring timely delivery of electronic devices while maintaining high levels of quality.

In conclusion, deburring machines offer significant efficiency and time savings in the sheet metal fabrication process. By automating the deburring process, manufacturers can achieve faster turnaround times, higher precision, and consistent quality. Case studies and examples from various industries highlight the advantages of using these machines to streamline production and meet tight project deadlines. Adopting deburring machines in sheet metal fabrication can lead to increased productivity and improved overall operational efficiency.

Deburring machines are highly efficient and time-saving tools in sheet metal fabrication, but they require regular maintenance to ensure optimal performance. Here are some tips for proper maintenance and upkeep of deburring machines:

• Regularly inspect the machine for any signs of wear or damage. Check for loose parts and tighten them as necessary.

• Clean the machine after each use to remove any debris or residual burrs. Use appropriate cleaning solutions and avoid using abrasive cleaners that could damage the machine.

• Lubricate moving parts regularly to prevent friction and ensure smooth operation.

• Keep the machine in a clean and dry environment to prevent corrosion and damage to electronic components.

• Follow the manufacturer's guidelines for maintenance intervals and procedures. This may include replacing worn-out parts or components at recommended intervals.

While deburring machines offer increased efficiency, it's essential to prioritize safety when operating them. Here are some safety protocols and precautions to consider:

• Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection.

• Familiarize yourself with the machine's operation manual and follow all safety instructions provided by the manufacturer.

• Ensure that the machine is well-maintained and in proper working condition before use to reduce the risk of accidents.

• Use proper guarding or protective devices to prevent accidental contact with moving parts.

• Avoid wearing loose clothing or jewelry that could potentially get caught in the machine.

• Keep the workspace clean and free of any tripping hazards.

• Do not exceed the machine's maximum capacity or load limits to avoid strain on the machine and potential accidents.

• Provide adequate training and supervision to operators to ensure they are aware of safety procedures and best practices.

By following these tips for maintenance and safety, you can maximize the efficiency and lifespan of your deburring machine while ensuring the well-being of operators. Prioritizing maintenance and safety considerations is crucial for a smooth and productive sheet metal fabrication process.

Deburring machines play a vital role in enhancing precision and ensuring high-quality finishes in sheet metal fabrication. With their ability to remove burrs and sharp edges, these machines not only improve the aesthetic appeal but also enhance the functionality and safety of fabricated components. By efficiently removing imperfections, deburring machines contribute to the overall accuracy and reliability of fabricated parts.

As technology continues to advance, deburring machines are likely to incorporate innovative features and capabilities. Some future advancements and trends in deburring technology may include:

• Integration of automation and robotics for increased efficiency and reduced labor costs.

• Improved precision and control through advanced sensors and monitoring systems.

• Enhanced versatility to accommodate a wider range of materials and geometries.

• Integration with digital systems and software for streamlined workflows and data analysis.

• Development of environmentally friendly deburring solutions that reduce waste and minimize the use of harmful chemicals.

These advancements and trends will further optimize the deburring process, making it faster, more precise, and cost-effective for sheet metal fabrication industries. By embracing these developments, manufacturers can stay competitive and meet the growing demands for high-quality finished products in various sectors.

Related news

CONTACT US

Address

53 Peng'an Road, Pingyao Town,

Hangzhou, China

kenny.gong@vip.163.com

17767176257@163.com

Phone

Phone:+86 17767171031

+86 13968085257

Fax:0571-88524367

JONSEN SANDER is one of the leading Sheet Metal Deburring Machines, Grinding Machine, Wide Belt Grinding Machine, Edge Rounding Machines Manufacturers, Factory and Suppliers, Our product quality has passed international certification, and the price is affordable, welcome to call and order our products wholesale.

Copyright: Hangzhou Xiangsheng Abrasive Machine Manufacturing Co., Ltd. Support By Hangzhou Great Master