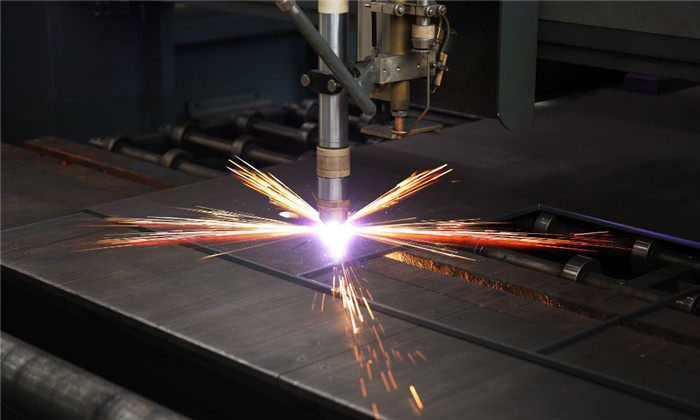

In the world of manufacturing precision, every detail matters. One tiny imperfection can compromise the quality and functionality of a product. This is where laser deburring comes in.

Laser deburring serves as a critical process designed to eliminate burrs—undesirable, uneven edges—from machined or manufactured parts. These burrs often result from various manufacturing processes like machining, drilling, or cutting. Traditional deburring methods, such as manual filing or abrasive blasting, prove to be time-consuming, labor-intensive, and inconsistent.

In contrast, laser deburring harnesses the power of high-energy laser beams to precisely melt and vaporize burrs, leaving a smooth, clean finished product in their wake. This automated and efficient process ensures uniformity and accuracy, minimizing the risk of human error and saving valuable time along the production line.

1. Precision and Consistency: Laser deburring sets itself apart by offering unparalleled precision, capable of targeting even the tiniest and most intricate parts. This guarantees consistent quality across all products, meeting the high standards demanded by industries such as aerospace, medical, and electronics.

2. Improved Efficiency: Laser deburring stands as a rapid and automated process, capable of eliminating burrs within seconds. This remarkable speed significantly accelerates production, slashing labor costs in comparison to manual deburring methods.

3. Enhanced Product Performance: By eradicating burrs, laser deburring elevates the functionality and performance of manufactured parts. Smooth edges and surfaces prevent interference, reduce friction, and preserve the structural integrity of the product.

4. Cost Savings: Despite the initial investment in laser deburring equipment, the long-term advantages far outweigh the costs. Increased productivity, reduced rework, and superior product quality lead to heightened customer satisfaction and lower overall manufacturing expenses.

In conclusion, laser deburring emerges as an indispensable process for refining manufacturing precision. Its precision, efficiency, enhanced product performance, and potential cost savings make it a pivotal tool for industries striving for excellence in their production processes.

Laser deburring, a cutting-edge technology, has reshaped the manufacturing landscape, delivering a precise and efficient solution for eliminating burrs and imperfections from metal parts. This breakthrough ensures an exceptional level of precision throughout the manufacturing process. For manufacturers seeking to elevate their precision in operations, here's an insightful guide to the world of laser deburring.

The core of laser deburring lies in its utilization of a highly focused laser beam, precisely directed to eliminate unwanted burrs and imperfections from metal surfaces. The laser beam meticulously melts away the material, leaving a flawlessly smooth surface. This controlled process can be finely programmed to remove burrs with remarkable accuracy, ensuring consistent and impeccable results across all parts.

One of the standout advantages of laser deburring is its non-contact characteristic. The laser beam never physically touches the part, effectively eliminating any risk of damage or deformation. This makes it especially suitable for intricate and delicate parts that prove challenging to deburr using conventional methods.

In the realm of laser deburring, different types of lasers find their application, each offering unique advantages. Here are the key laser variants commonly employed in laser deburring:

1. Fiber Lasers: Renowned for their exceptional power and beam quality, fiber lasers stand as the epitome of precision deburring. Their efficiency and seamless integration into automated manufacturing processes make them a top choice for meticulous operations.

2. Nd:YAG Lasers:Versatile Nd:YAG lasers find utility across a broad spectrum of deburring applications. With outstanding beam quality and the capability to deliver high peak power, they excel in efficient material removal.

3. CO2 Lasers: Tailored for deburring larger parts or thicker materials, CO2 lasers boast high average power and swift burr removal capabilities. They offer a swift pace of material removal, making them ideal for certain applications.

Laser deburring systems are gaining immense traction in the manufacturing industry, driven by their ability to facilitate precise and controlled material removal. By investing in this cutting-edge technology, manufacturers unlock avenues to augment precision, enhance product quality, and elevate overall operational efficiency. Step into the future of manufacturing precision with laser deburring.

Laser technology stands as a beacon of transformation within the manufacturing realm, presenting a multitude of advancements, among which its role in deburring processes is of paramount significance. Deburring, the meticulous elimination of unwanted rough edges and burrs from metal components, finds a potent ally in laser deburring. This method offers precise and efficient results, significantly elevating manufacturing precision. Let's delve into the domains where laser deburring showcases its prowess and benefits.

The automotive industry, a domain where precision and quality control are non-negotiable, finds laser deburring to be a pivotal player. It ensures that critical metal parts, ranging from engine cylinders to gears and connectors, boast impeccably smooth, burr-free edges. The significance of this goes beyond aesthetics; smooth surfaces mitigate the risk of component damage, reduce friction, and amplify overall performance.

In the automotive landscape, laser deburring bestows a spectrum of advantages. Its automated prowess negates the need for labor-intensive manual deburring, thus saving both time and costs. Furthermore, the non-contact nature of laser technology translates to a gentle touch on delicate parts, safeguarding their durability and longevity. The consistency of laser deburring, marked by its highly repeatable process, guarantees uniform perfection across each component.

Precision assumes a towering stature in the aerospace industry, and laser deburring rightfully claims its throne in the realm of aerospace component manufacturing. Turbine blades, fuel nozzles, engine parts—laser deburring is the trusted guardian of these critical components. The high precision and fine-tuned control of lasers ensure the removal of burrs without compromising critical dimensions or part integrity.

Embracing laser deburring translates to a proactive adherence to stringent quality standards within the aerospace domain. The precision endowed by laser technology significantly minimizes the risk of damage to delicate or complex parts, reinforcing their functionality and reliability.

In summation, laser deburring stands as an indispensable manufacturing process, notably in the automotive and aerospace domains. Its remarkable ability to precisely and consistently remove burrs amplifies the overall quality of metal components. Manufacturers embracing laser deburring techniques reap the rewards of heightened efficiency, reduced costs, and the ability to deliver superior products, aligning seamlessly with the exacting demands of their respective industries. Step into the future of manufacturing precision with laser deburring at the helm.

In the realm of manufacturing, precision stands as the bedrock for exceptional product quality and error reduction. Among the arsenal of tools to achieve this, laser deburring emerges as a powerful technique, meticulously eliminating unwanted burrs and sharp edges from machined components.

Laser deburring offers numerous advantages for manufacturers seeking to improve the quality and precision of their products:

1. Consistent Results:Laser deburring ensures unwavering precision, delivering consistent results across myriad components. The method eradicates variations inherent in manual deburring techniques, ultimately upholding an elevated standard of precision in the final product.

2. Increased Surface Finish: The use of lasers leaves a mark of uniformity, rendering a smooth and flawless surface finish post-deburring. By eradicating burrs and imperfections, the product not only looks pristine but functions optimally, paving the way for heightened customer satisfaction.

3. Enhanced Product Performance:Laser deburring excels in removing burrs that could impede product performance—interfering fits, friction issues, or efficiency reduction in moving parts. This meticulous process results in products that are not just reliable but also superior in functionality.

Implementing laser deburring in the manufacturing process can lead to notable time and cost savings:

1. Increased Efficiency: Laser deburring is a highly efficient process, allowing manufacturers to deburr multiple parts simultaneously. This reduces production time and eliminates the need for manual deburring methods that can be time-consuming and labor-intensive.

2. Reduced Scrap and Rework: With laser deburring, manufacturers can significantly reduce the occurrence of burrs and defects that may lead to rejected parts or the need for rework. This not only saves production time and material costs but also minimizes waste and improves overall manufacturing efficiency.

3. Improved Production Workflow: Laser deburring can be seamlessly integrated into the production line, optimizing the overall workflow. Its automated and precise nature reduces human error and ensures smooth operations, leading to improved productivity and reduced downtime.

By incorporating laser deburring into the manufacturing process, businesses can achieve enhanced product quality, increased precision, reduced production time, and cost savings. It is a valuable technique that empowers manufacturers to deliver high-quality products efficiently and remain competitive in the market.

When it comes to enhancing manufacturing precision, laser deburring is a game-changer. It offers a precise and efficient way to remove burrs and imperfections from machined parts, resulting in smoother surfaces and improved functionality. If you're considering implementing laser deburring in your manufacturing process, here's a guide to help you choose the right system.

1. Power and Speed: The power and speed of the laser are essential considerations. Higher power lasers can remove burrs more efficiently, but they may also cause unwanted heat effects. Ensure that the laser system you choose offers the right balance between power and speed for your specific application.

2. Flexibility: Look for a laser deburring system that offers flexibility in terms of part size, material, and shape. This ensures that you can tackle a wide range of deburring tasks without limitations.

3. Precision and Accuracy: Check the system's precision and accuracy specifications to ensure it meets your desired tolerances. Laser systems with advanced control and monitoring capabilities can deliver precise and consistent deburring results.

4. Reliability and Maintenance: Consider the reliability and maintenance requirements of the laser deburring system. Look for robust construction, high-quality components, and easy accessibility for maintenance and repairs.

1. Trumpf TruMicro Mark Series: This laser system offers high-power and high-speed capabilities, suitable for a wide range of applications. It features advanced scanning technology for precise and efficient deburring.

2. Coherent StarFiber Series: The StarFiber series provides excellent flexibility and versatility. It offers different power options and can be easily integrated into existing manufacturing processes.

3. IPG Photonics' LaserCube: The LaserCube is a compact and cost-effective solution for laser deburring. It offers high-speed processing and can be easily automated for increased productivity.

4. Amada Miyachi ML-8150A: This system combines a high-power fiber laser with advanced control features. It allows for precise and repeatable deburring on a variety of materials.

In conclusion, choosing the right laser deburring system involves considering factors such as power, speed, flexibility, precision, and reliability. By selecting the appropriate system for your specific needs and exploring popular options on the market, you can enhance manufacturing precision and improve the quality of your machined parts.

When it comes to enhancing manufacturing precision, laser deburring is a game-changer. This meticulous process removes burrs, sharp edges, and imperfections from metal components, resulting in smoother surfaces and increased product quality. Here are some best practices to follow to ensure effective and safe laser deburring in your manufacturing process.

Preparation: Before starting the deburring process, it's crucial to thoroughly clean the components to remove any dirt, oil, or contaminants. This ensures optimal laser penetration and prevents damage to the equipment.

Safety Measures: Laser deburring involves the use of powerful lasers, so safety should be a top priority. Proper training on laser safety protocols and the use of personal protective equipment (PPE) such as safety glasses and gloves are essential. Additionally, ensure that there are proper ventilation systems in place to control fumes and prevent accidents.

To achieve precise deburring results, it's important to optimize the deburring parameters based on the specific requirements of your components. Here are some key factors to consider:

Laser Power: Determining the right laser power level is crucial for efficient deburring. It should be set at an intensity that effectively removes burrs without causing any damage to the component's surface.

Pulse Duration: The pulse duration of the laser should be adjusted based on the material being deburred. Shorter pulses are more effective for removing smaller burrs, while longer pulses are better suited for larger burrs or thicker materials.

Spot Size: The size of the laser spot can significantly impact the precision of the deburring process. Smaller spot sizes provide higher precision, but they may also require increased scanning time. Balancing spot size and scanning speed is key to achieving optimal results.

By following these best practices, you can enhance manufacturing precision through laser deburring. Remember to prioritize safety, thoroughly prepare the components, and optimize the deburring parameters to achieve the desired results efficiently.

In the field of medical device manufacturing, precision is crucial to ensure the highest level of quality and safety. One common challenge faced by manufacturers is the presence of burrs on metal components, which can impact the functionality and performance of the devices. This is where laser deburring comes in.

By using laser technology, medical device manufacturers have been able to achieve enhanced precision in their production processes. Laser deburring is a non-contact method that utilizes high-energy laser beams to remove burrs and other unwanted material from the surface of metal components. This process not only ensures a smooth and clean finish, but it also eliminates the risk of damaging delicate parts.

Through the implementation of laser deburring, medical device manufacturers have experienced significant improvements in their production efficiency and product quality. The precise and controlled nature of laser deburring eliminates the need for manual labor and reduces the risk of human error. This results in consistent and repeatable deburring results, thereby improving overall manufacturing precision.

The production of electronic components often involves intricate designs and tight tolerances. Burrs that form during machining processes can negatively impact the functionality and reliability of these components. Laser deburring has proven to be a valuable solution in improving manufacturing precision in this industry as well.

By utilizing laser technology, electronic component manufacturers have been able to eliminate burrs and other imperfections on their products. The high precision and accuracy of laser deburring ensure that each component meets the required specifications, resulting in improved product performance and customer satisfaction.

Moreover, laser deburring offers a significant advantage in terms of production efficiency. Traditional deburring methods often require extensive manual labor and can be time-consuming. Laser deburring, on the other hand, is a fast and automated process that can be seamlessly integrated into the production line. This not only speeds up the manufacturing process but also reduces costs by minimizing the need for additional labor.

In conclusion, laser deburring has proven to be a game-changer in enhancing manufacturing precision in sectors such as medical device manufacturing and electronic component production. By eliminating burrs and ensuring smooth and clean surfaces, laser deburring improves product quality, increases production efficiency, and ultimately contributes to the success of these industries.

In conclusion, laser deburring is a highly effective and efficient technique for enhancing manufacturing precision. By using focused laser beams, this process can remove burrs from various materials, resulting in smoother surfaces and improved product quality. Laser deburring offers several benefits, including increased productivity, reduced costs, enhanced safety, and improved part performance.

The use of laser deburring in manufacturing precision brings several advantages across different industries. First, laser deburring saves time and increases productivity by eliminating the need for manual deburring methods. The automation of this process allows for faster production cycles and reduces labor costs. Additionally, laser deburring ensures consistent and precise results, leading to improved part performance and reduced scrap rates. This technique is applicable to a wide range of materials, including metals, ceramics, and plastics, making it versatile for various manufacturing applications.

Moreover, laser deburring enhances workplace safety by eliminating the risks associated with manual deburring, such as sharp edges and repetitive strain injuries. The non-contact nature of laser deburring also minimizes the chances of damage to delicate or complex components. Overall, the benefits of laser deburring in manufacturing precision make it an invaluable technique for achieving higher quality products and streamlining production processes.

As technology continues to advance, the future of laser deburring holds promising developments. Laser systems are becoming more sophisticated, allowing for greater precision and control during the deburring process. The integration of artificial intelligence and machine learning algorithms can optimize laser parameters, leading to even more efficient and effective deburring. Additionally, advancements in laser optics and beam delivery systems will further enhance the capabilities of laser deburring.

Furthermore, the industry is exploring the use of ultrafast lasers for deburring applications, enabling precise material removal without causing thermal damage. This innovation opens up opportunities for deburring on a microscale level, ideal for industries such as electronics and medical device manufacturing.

In conclusion, laser deburring is a rapidly evolving technology that offers immense potential for enhancing manufacturing precision. By embracing these advancements, manufacturers can stay ahead of the competition and achieve superior quality products with increased efficiency and cost-effectiveness.

Related news

CONTACT US

Address

53 Peng'an Road, Pingyao Town,

Hangzhou, China

kenny.gong@vip.163.com

17767176257@163.com

Phone

Phone:+86 17767171031

+86 13968085257

Fax:0571-88524367

JONSEN SANDER is one of the leading Sheet Metal Deburring Machines, Grinding Machine, Wide Belt Grinding Machine, Edge Rounding Machines Manufacturers, Factory and Suppliers, Our product quality has passed international certification, and the price is affordable, welcome to call and order our products wholesale.

Copyright: Hangzhou Xiangsheng Abrasive Machine Manufacturing Co., Ltd. Support By Hangzhou Great Master