Metal sander grinder SG1650-WJS+B is widely used in the applications of whole sheets or large scaled parts precision grinding to certain thickness, precision surface sanding to certain surface roughness, and etc. Suitable materials includes titanium, molybdenum, aluminum, stainless steel, and carbon steel.

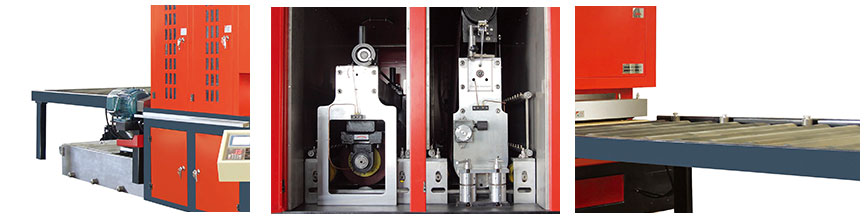

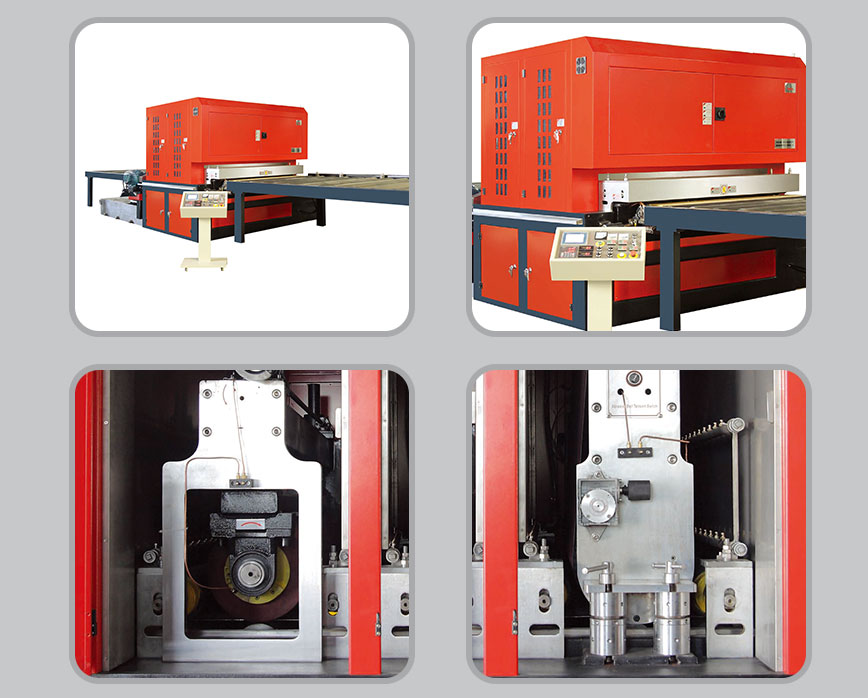

Product details presentation

Machine characteristic overview

Wheel polishing machine

1. Wet operation.

2. SKF precision bearings are used to achieve optimal performance and durability.

3. Heavily constructed machine frame for longer machine life span.

4. Rubberized roller type conveyor to provide smooth feeding.

5. Optional connecting roller conveyors at machine entrance and exit for feeding and receiving long and heavy parts, sync height movement with the machine.

6. Automatic cutting fluid filtration unit.

7. Optional reciprocating type processing.

8. Maximum working width: 1300mm/1650mm/1900mm.

Optional configuration

Modular and various combinations of wide abrasive belt heads and polishing barrels are available

Technical datasheet

|

Maximum working width

|

1580mm

|

Working thickness range

|

0.5-40mm

|

|

Minimum working length

|

700mm

|

Wide abrasive belt dimension

|

1650x2620mm

|

|

Conveyor feeding rate

|

2-18m/min

|

Total power

|

97.5kw

|

|

Machine dimension

|

3500x3300x2260mm

|

Machine weight

|

8000kgs

|

Applications

Metal sander grinder SG1650-WJS+B is capable of following applications: precision grinding to certain thickness, precision surface sanding to certain surface roughness, surface roughening, surface finishing & polishing, and etc. The conveyor table can be configured to reciprocating movement, hence especially for large and heavy parts, it can be processed by the work stations with multiple passes.

Metal sander grinder - By exchanging different grit wide abrasive belt, specific surface requirement can be achieved. Work stations are modular and configurable to achieve specific requirements, for example double wide abrasive belt heads, single wide abrasive belt head + polishing barrel station, and etc.

To buy Sheet Metal Deburring Machines, choose JONSEN SANDER, JONSEN SANDER is one of the leading Sheet Metal Deburring Machines, Wide Belt Grinding Machine, Wide Belt Grinding Machine Manufacturers, Factory and Suppliers, Our product quality has passed international certification, and the price is affordable, welcome to call and order our products wholesale.>>>Flat metal deburring machines

CONTACT US

Address

53 Peng'an Road, Pingyao Town,

Hangzhou, China

kenny.gong@vip.163.com

17767176257@163.com

Phone

Phone:+86 17767171031

+86 13968085257

Fax:0571-88524367

JONSEN SANDER is one of the leading Sheet Metal Deburring Machines, Grinding Machine, Wide Belt Grinding Machine, Edge Rounding Machines Manufacturers, Factory and Suppliers, Our product quality has passed international certification, and the price is affordable, welcome to call and order our products wholesale.

Copyright: Hangzhou Xiangsheng Abrasive Machine Manufacturing Co., Ltd. Support By Hangzhou Great Master